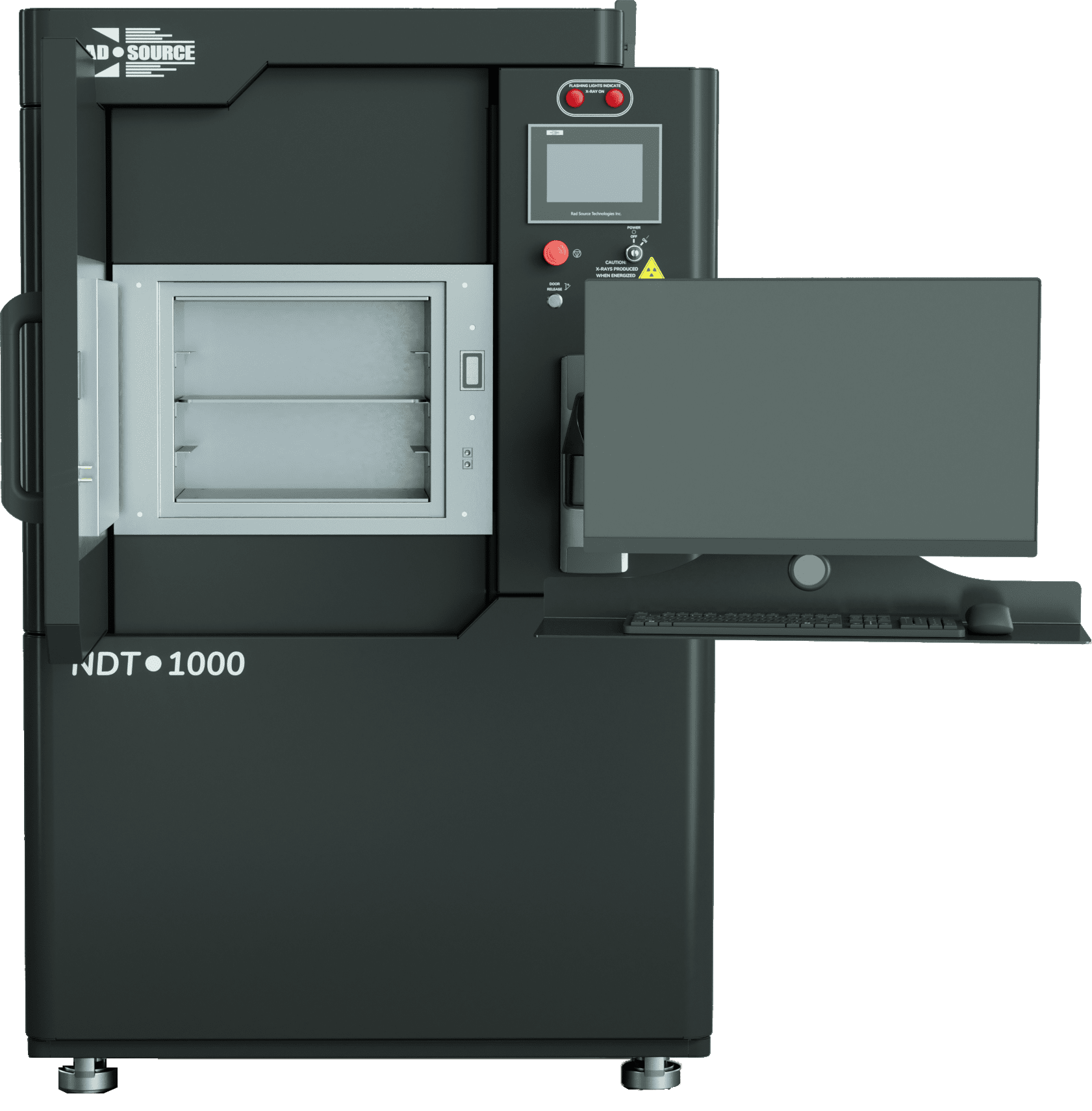

NDT 1000 X-ray Inspection System

The Science of Seeing the Unseen™

Inspection Power, Speed, and Material Flexibility

The NDT 1000 inspects thicknesses of up to 0.5″ – including steel – with images of 24 fps and a high resolution digitizing panel and monitor.

Flexible, Fast, and Powerful

The NDT 1000 has the capability to efficiently inspect materials and assemblies in industries where quality is a top priority, including aerospace, defense, automotive, and testing services. Materials of up to 0.5″ thick, including steel piping and welds, can be inspected in one second.

High Resolution:

4K digitizing panel and monitor.

On-Screen Annotation:

Customizable DICONDE Tags can be added to images.

Image Averaging:

Noise is reduced by averaging each pixel for up to 8 frames.

Image Filtration:

Brightness, contrast, inversion, binarize, smooth, sharpen.

Adjustable Magnification:

Four shelf locations to change the image size.

Measuring Tool:

Four shelf locations to change the image size.

File Management:

Store on hard disc and transfer via WI-FI or USB port. Load existing images for manipulation.

Hassle-Free Ownership. Easy to Use.

- No training necessary

- Compact size and portability

- Castor wheels

- Worry-free maintenance

- Uses a standard 120 Volt outlet

- No external cooling system required

Options

Automatic Defect Recognition:

Customized for each customer for material and defect type.

Pass Through Inspection:

Custom process-control for high-throughput and inspection results feedback.

Service

- Unrivaled X-ray solutions support from a highly trained and responsive global service and support team. We are able to service X-ray systems from all manufacturers

Equipment Dimensions (W x H x D)

45 x 72.5 x 31″

114 x 183 x 79 cm

Internal Chamber Dimensions (W x H x D)

16.4 x 12.7 x 14.9″

41.7 x 32.2 x 37.8 cm

Equipment Weight

1,400 lb

635 kg

Imaging Area (dependent on shelf level)

7.5” x 7.5” / 19 x 19 cm

Pixel Size

152 µm

Scintillator

Cesium iodide

Magnification

up to 1.5x

Energy Range

30 – 160 kV

Electrical Requirements

120 VAC, 10A

Tube Current

1 – 4 mA

Focal Spot Size

0.5 mm

Inherent Filtration

1.5 mm ultem, 9.0 mm oil, 1.7 mm glass, 0.8 mm beryllium

INSTALLATION:

• For the installation, the unit will arrive at your facility in the morning and will be met by our install team

• All NDT 1000 Inspection Systems receive a quality inspection, and radiation survey prior to shipment and again at installation

• On-site Training Included at installation

Cooling Requirements:

• Not Required

WARRANTY INFORMATION

• 12 month full warranty: Including all parts, labor, and travel

• Service Agreement Program: Available for purchase anytime within 12 months from date of installation

– Includes ALL parts, labor, travel and one PM call per annum

- Rad Source NDT Inspection Systems receive a quality inspection, and radiation survey prior to shipment and again at installation

- Rad Source NDT Inspection Systems are manufactured as cabinet X-ray devices and conform to the radiation safety guidelines in US CFR 1020.40

Contact Our Experts

FAQs

What is the penetration capability of this system?

This system produces 160 kV at 4 mA which is capable of penetrating approximately 0.5″ of steel.

Is this a real time x-ray system?

Yes, this system has a frame rate of 24 frames per second. The higher the resolution the slower the frame rate typically is. With additional hardware it is possible to produce even higher frame rates. This is only necessary when inspecting samples in motion. If this equipment is provided with motion hardware we must consider the speed of inspection.

Can this equipment be provided with additional hardware for motion inspection?

Yes, this unit is the basis of many different inspection procedures. The unit can be provided with an internal manipulator or a pass-through conveyor system.

Can this unit be provided with other imaging panels?

Yes, the standard for this system is a 9 inch square imaging plate. Smaller plates can be integrated into the system as well. Many times a smaller plate produces high resolution within the pixels.

Can this system be provided with a microfocus x-ray source?

Yes, the configuration is very different to allow high magnification of the sample being inspected. A micro focus system is typically up to 130 kV at 300 microamps. The focal spot is approximately 10 to 20 microns in size.

Can this system overheat?

Yes, depending on the environment and the operational temperature the system has the ability to overheat. There is a thermal protection system that controls the X-ray on condition if the over temperature sensor is tripped. This is done to protect the system from damage.

Can this system be tied to a network?

Images can be stored on the provided industrial PC or transferred via Wi-Fi or USB port. Also, existing images can be loaded for manipulation.

Can the image capture software perform any modifications to the image?

The image software allows standard control of the image such as brightness and contrast modifications as well as some convolutions. Other features are available on request.

Is this system radiation safe?

Yes, this system meets and exceeds Federal standard 21 CFR 10 20.40. All doors and covers are provided with interlocks or switches as required. The lead thickness of this unit exceeds typical shielding requirements of radiation enclosures.

Is the power of the X-ray source controllable by the operator?

The KV and mA are independently controllable by a software interface. The graphic user interface allows the operator to have direct control of the kV and mA.